Ford Focus Service Manual: Cylinder Head Distortion

|

Feeler Gauge Set 303-D027 (D81L-4201-A) or equivalent |

NOTE:

Refer to the appropriate Section 303-01 for the specification.

- NOTE:

Make sure all cylinder head surfaces are clear of any gasket material, silicone sealant, oil and coolant. The cylinder head surface must be clean and dry before running a flatness check.

NOTE:

Use a Straightedge that is calibrated by the manufacturer to be flat within 0.005 mm (0.0002 in) per running foot of length, such as Snap-On® GA438A or equivalent. For example, if the Straightedge is 61 cm (24 in) long, the machined edge must be flat within 0.010 mm (0.0004 in) from end to end.

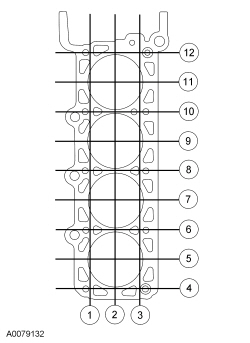

Using a Straightedge and a Feeler Gauge Set, inspect the cylinder head for flatness in the sequence shown.

Cylinder Head - Engine - 2.0L - in Vehicle Repair

Cylinder Head - Engine - 2.0L - in Vehicle Repair

Special Tool(s)

Alignment Plate, Camshaft

303-465 (T94P-6256-CH)

Engine Support Bar

303-F072

Material

Item

Specification

...

Cylinder Head Temperature (CHT) Sensor

Cylinder Head Temperature (CHT) Sensor

Item

Part Number

Description

1

9H589

Cylinder Head Temperature (CHT) sensor electrical connector

2

12A674

CHT sensor

Removal and Inst ...

More about Ford Focus:

Ford Focus Inspection and Repair After a Supplemental Restraint System (SRS) Deployment

WARNING: Remove

restraint system diagnostic tools from the vehicle prior to road testing. If tools

are not removed, the supplemental restraint system (SRS) device may not deploy in

a crash. Failure to follow this instruction may result in serious personal injury

or death in a crash and possi ...